The material consequences of choosing sustainable fashion

The textile industry – primarily the business of cloth and clothing – produces close to 100 million tonnes of fibres every year. This number is only set to grow as purchasing power in emerging markets rises.

The industry – and its growth – has huge consequences for the environment and climate change, producing some 1.2 billion tonnes of CO2 equivalent per year. However, an increasing number of consumers, aware of the impact that clothing choices can have on the environment, are changing their buying habits.

For an industry that makes $3 trillion per year in revenues and employs nearly 60 million workers globally, this has material consequences for investors too.

In facts and figures

– 66 per cent of global consumers say they are willing to pay more for sustainable goods – up from 55 per cent in 2014 and 50 per cent in 2013, according to Nielsen data.

– Millennials continue to be most willing to pay extra for sustainable offerings – almost three-out-of-four respondents in the latest findings, up from approximately half in 2014.

– In emerging markets, more than 65 per cent of emerging consumers have been found to actively seek out sustainable fashion1.

What’s wrong with textiles?

Even if we focus just on carbon emissions and water consumption, textile production is one of the most polluting industries globally.

Carbon

The textile industry produces more carbon than international flights and maritime shipping. The production of 1 tonne of textiles generates 17 tonnes of CO2 equivalent, compared to 3.5 tonnes for plastic and less than 1 tonne for paper2.

Source: SEI

Over 60 per cent of textiles are used in the clothing industry, and a large proportion of clothing manufacturing occurs in China and India, countries that rely on coal-fuelled power plants. This increases the carbon footprint of each garment.

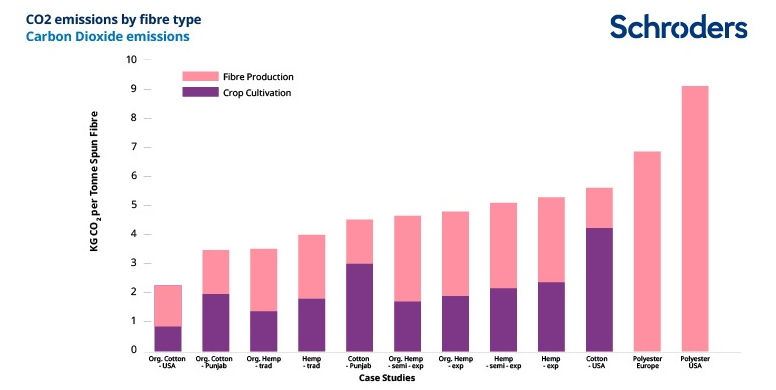

The materials produced also has a noticeable effect on emissions from manufacturing. It is estimated that a single polyester t-shirt has emissions of 5.5 kg CO2, compared with 2.1 kg CO2 for one made from cotton3.

If the industry continues on its current path, by 2050, it could use more than 26 per cent of the carbon budget “allowed” by the Paris Accord 4to keep global temperature rises to the 2°C target.

Water

Textiles production (including cotton farming) uses around 93 billion cubic metres of water annually, representing 4 per cent of global freshwater withdrawal5. Cotton, while less carbon intensive than polyester, is the most water intensive fibre to produce.

Beyond production, washing clothing using washing machines is estimated to require an additional 20 billion cubic metres of water per year globally6.

The greatest challenge is accessing the water required in water-scarce regions. At present, many of the key cotton-producing countries are under high water stress, including China, India, the US, Pakistan, and Turkey7. In China, 80 per cent to 90 per cent of fabric, yarn, and plastic-based fibres are made in water-scarce or water-stressed regions8.

Furthermore, while there is little data on ” substances of concern” used across the industry, it is recognised that textile production discharges high volumes of water containing hazardous chemicals into the environment. As an example, the World Bank estimates that 20 per cent of industrial water pollution globally is attributable to the dyeing and treatment of textiles9.

Read more:

- What is the Green New Deal and what does it mean for investors?

- Trash talk: why waste might not be wasted

- SustainEx: Quantifying the hidden costs of companies' social impacts

What are the solutions?

There are several ways the textiles industry can tackle these problems. Fibre producers that have sustainable sourcing (ie. that have certified & controlled sources), have “closed loop” systems avoiding waste, and have sustainable processing of biomass – ideally powered by renewable energy sources – have the best carbon footprints. These “bio refineries” generate pulp, bio based chemicals and energy.

There are also emerging innovations that change the way textiles are dyed in order to save water, chemical and energy use. Digital printing is one example.

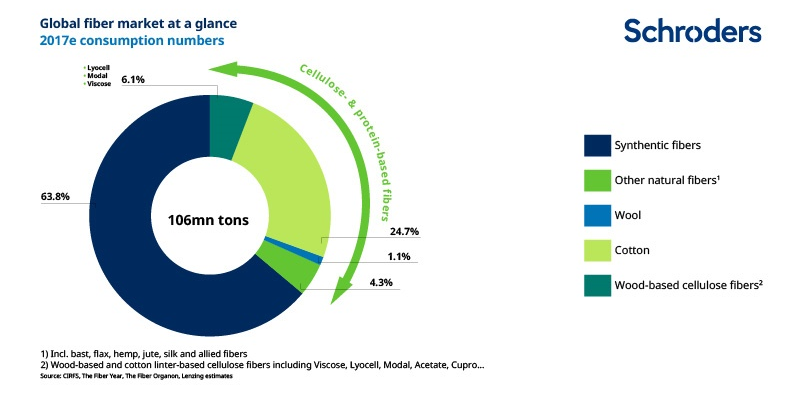

One of the most effective changes could be promoting wood-based “cellulosic” fibre use. Synthetic fibres are used more than natural fibres, and of the latter, cotton still leads. Cotton and polyester dominate the fibre market, accounting for 85 per cent of all fibre used in clothing. Cotton production is very water and pesticide intensive, whereas polyester and nylon have very poor carbon footprints. Synthetics are also not biodegradable.

Wood based cellulosic fibres are only 6 per cent of fibres in use today, but their use is outgrowing other fibres. “Modal fibres” are a type of cellulosic fibre developed in Japan in 1951. They are made from regenerated cellulose fibre.

Modal is 50 per cent more water absorbent per unit volume than cotton, and consumes less water in production. Modal is also resistant to shrinkage, stays colour fast when washed in warm water, and is breathable and silky smooth to the touch. Modal fibre is a generic name for viscose/rayon, which comprise 90% of all cellulosic fibres. Modal fibre is produced according to a modified viscose process and has better textile properties, therefore it is a separate generic fibre.

Lyocell is a fibre made from the natural polymer cellulose found in wood. It is 100 per cent biodegradable, and a sub-category of rayon. It is made in a closed loop process, which means the water and non-toxic solvents are virtually all reused.

Cellulosic fibres like lyocell and modal consume far less energy than synthetic fibres, and consequently are lower carbon emitters than the main alternatives on the market. They also don’t have the water withdrawal issues that cotton possesses.

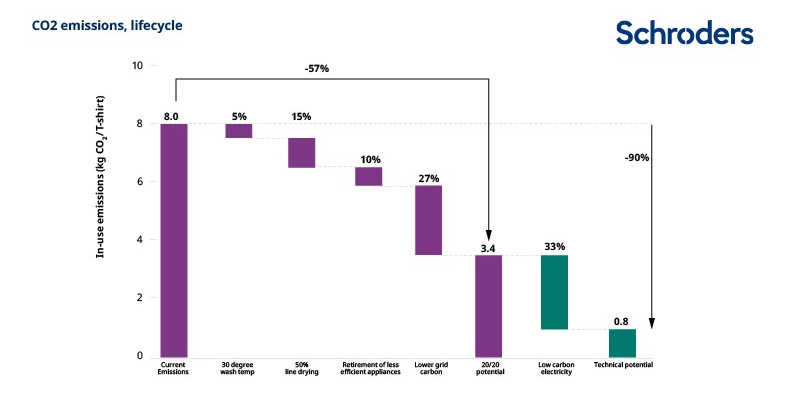

Using these types of fibres could further limit the climate damage from textiles or clothes through their life cycle. Most life cycle emissions of clothes arise from the “use” phase. If we model a scenario of 50 uses of a cotton t-shirt, more emissions come from the use phase of clothing than from other activities.

Source: Carbon trust

Washing and drying clothing alone is estimated to account for 120 million tonnes of CO2 equivalent10. Fast drying products – able to improve appliance efficiency through lower temperature washing – could offer a major improvement upon the emissions associated with existing fibres.

Some fibres can enable faster drying, mainly cellulose and wool blends. Home appliances are also getting more efficient, which will help reduce carbon emissions. More recycling of fibres/extension of garment life – ie. “slower” fashion and better quality items – will also help.

The climate change impact of recycling worn out polyester or cotton waste into new polyester or cotton fibre is much lower than making the fibre from scratch. In addition, the dominance of the “use” phase emissions means that if garment lives can be extended, we can achieve strong carbon emission savings.

What is being done?

Textiles is an industry that contributes close to 10 per cent to global carbon emissions. We see considerable potential to reduce this by focusing on cellulosic fibres, using digital printing, and improving resource preservation, as well as focusing more on recycling and in-use emissions.

Change, encouragingly, is looking more likely now than ever. The UK Parliament's Environmental Audit Committee published its proposals for improving the sustainability of the fashion industry in February. Recommendations include strengthening the Modern Slavery Act, using taxation as a way to penalise companies selling products with higher environmental impacts, and introducing an Extended Producer Responsibility scheme to reduce waste.

There is growing momentum in China too, which has focused on building a greener supply chain within the fashion and textile industries for some time, via its five-year plan. In January, the China National Textile and Apparel Council revealed national ambitions to forge a new image under three new labels “Technology, Fashion and Green” and it specified intentions to tighten its grip on environmental issues.

- To read more views from Schroders' sustainability experts and discover their approach to investing sustainably visit the Sustainable Investment hub.

1. Source: Cotton Lifestyle Monitor (n.d.) as cited in Business of Fashion (2016), The State of Fashion 2017↩

2. Source: Eunomia, The potential contribution of waste management to a low carbon economy (2015)↩

3. This is because the former is produced from fossil fuels such as crude oil. In 2015, production of polyester for textiles use results in more than 706 billion kg of CO2e↩

4. Compared to the IEA 2°C pathway 2050 which allows for 15.3 giga tonnes of CO2 equivalent↩

5. Source: World Bank, AQUASTAT, and FAO, Dataset: Annual freshwater withdrawals, total (2014) ↩

6. Calculation based on Circular Fibres Initiative analysis and following sources: Pakula, C., Stamminger, R., Electricity and water consumption for laundry washing by washing machine worldwide (2009)↩

7. Source: Gassert, F., et al., Water stress by country, WRI Aqueduct (2013)↩

8. Source: Maxwell, D., et al., State of the apparel sector report: Water, GLASA (2015), p.43↩

. Source: Kant, R., Textile dyeing industry: An environmental hazard, Natural Science, Vol. 4, 1 (2012), p.23↩

10. Source: Calculation based on Circular Fibres Initiative analysis and following sources: Pakula, C., Stamminger, R., Electricity and water consumption for laundry washing by washing machine worldwide (2009); Dupont, Consumer Laundry Study (2013)↩

Important Information: The views and opinions contained herein are of those named in the article and may not necessarily represent views expressed or reflected in other Schroders communications, strategies or funds. The sectors and securities shown above are for illustrative purposes only and are not to be considered a recommendation to buy or sell. This communication is marketing material.

This material is intended to be for information purposes only and is not intended as promotional material in any respect. The material is not intended as an offer or solicitation for the purchase or sale of any financial instrument. The material is not intended to provide and should not be relied on for accounting, legal or tax advice, or investment recommendations. Reliance should not be placed on the views and information in this document when taking individual investment and/or strategic decisions. Past performance is not a guide to future performance and may not be repeated. The value of investments and the income from them may go down as well as up and investors may not get back the amounts originally invested. All investments involve risks including the risk of possible loss of principal. Information herein is believed to be reliable but Schroders does not warrant its completeness or accuracy. Reliance should not be placed on the views and information in this document when taking individual investment and/or strategic decisions. The opinions in this document include some forecasted views. We believe we are basing our expectations and beliefs on reasonable assumptions within the bounds of what we currently know. However, there is no guarantee than any forecasts or opinions will be realised. These views and opinions may change. Issued by Schroder Investment Management Limited, 1 London Wall Place, London, EC2Y 5AU. Registration No. 1893220 England. Authorised and regulated by the Financial Conduct Authority.