Sustainable By Design, Scientifically Proven.

Life Cycle Assessment – Performed by the LCA Centre

SUMMARY

1. CORPLEX presentation

2. Designing for the circular economy

3. Correx® Flower Box Life Cycle Assessment

4. Circular economy products at a glance

CIRCULAR PLASTIC BY DESIGN

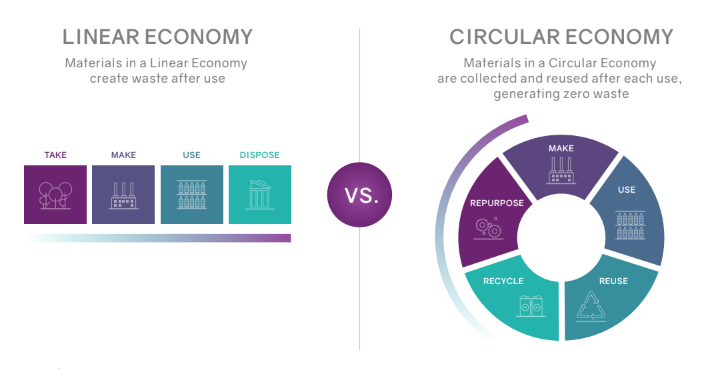

Working closely with our customers, we have managed to create a broad array of tailor-made storage, transit, and packaging solutions for our clients, in parallel to off-the-shelf, standardised solutions that fully apply the 5R’s methodology to product design (Remove, Reduce, Reuse, Recycle and Repurpose).

We have also implemented a Plastics Recovery Program consisting of collecting back the polypropylene products from our clients, mechanically grinding end-of-life products, and reusing the resin to make new products with the same use, without downgrading. A service over which we have undisputable know-how: our recycling division was founded back in 1977.

Working closely with our customers, we have managed to create a broad array of tailor-made storage, transit, and packaging solutions for our clients, in parallel to off-the-shelf, standardised solutions that fully apply the 5R’s methodology to product design (Remove, Reduce, Reuse, Recycle and Repurpose).

WE THINK GLOBAL AND ACT LOCAL

Our sales and manufacturing facilities are strategically located in France, the United Kingdom, Spain, Slovakia and the USA. The perfect packaging solution is waiting for you!

ABOUT CORPLEX

CORPLEX is a global plastics solution manufacturer,present at every step of the supply chain cycle. We offer logistics and storage packaging solutions,shaping customer needs into sustainable solutions in multiple industries. Through more than half a century of experience, we have built a market leader position by offering innovative products and services. With more than 650 employees across our 11 sites in Europe and the USA, we are committed to working closely with our customers to develop and manufacture efficient solutions to reduce the impact of their business on the environment.Our extensive range of products and applications are perfectly placed to take on the challenge of providing innovative products that reduce carbon footprint.

Corplex Packaging Solutions: A Comparative Assessment

Correx® FLOWERBOX

The Correx® Flower Box is a durable, reusable, and foldable box made of fluted polypropylene which gives excellent strength properties. Its design is the result of a precise and careful consideration of the logistic needs of our clients. A unique architecture allows it to collapse flat, increasing space when empty and optimizing handling, storage, and logistics flows. Lightweight, it is also moisture and weather-resistant, capable to withstand ultra-low temperatures. The Correx® Flower Box is available in a variety of colors, can be customized in size and thanks to its excellent printing surface is ready to be branded. By adding separators into the box, the fragile and sensitive goods will be highly protected during transport.

RECYCLABLE: A PERFECT APPLICATION OF CIRCULAR ECONOMY PRINCIPLES

CORPLEX implements a cradle-to-cradle design approach for its solutions. Our Correx® Flower Box is designed to last, and can be reused for 40+ trips, thanks to high-end materials… that are fully recyclable as well: after its end of life, the Correx® Flower Box is re-manufactured into new products through a process that uses 89% less water and generates 44% less CO2 emissions than cardboard recycling. Let’s see how, compared to a cardboard box, our solution also has an edge in terms of Global Warming Potential.

Life Cycle Assessment

Scope of the assessment

CORPLEX, a polypropylene plastic extruder, and its Circular Alliance partners sought to understand the true environmental impact of a reusable plastic box compared to its equivalent single-use cardboard box. Boxes were studied in a real life scenario to transport cut fresh flowers from a DC in the Netherlands to various points of sale in the UK.

The LCA study was conducted according to ISO 14040 and ISO 14044 standards and it has been reviewed by two independent peer reviewers with the associated technologically relevant knowledge. Additionally, a tool was created to establish breakeven points at which both boxes emit the same quantity of CO2 (measured in kg CO2-eq). The functional unit used for this study is one horizontal box (base and lid) with a volume of approximately 130 liters to hold fresh cut flowers transported between the Netherlands to specific points in the UK.

The end-of-life scenarios for both the cardboard and plastic box within this study is recycling, while parts of the tertiary packaging are either recycled or incinerated.

The CORPLEX reusable and foldable plastic box is manufactured out of fluted polypropylene that has recycled content from damaged boxes from within this system. It is designed to be robust but affordable, to encourage parties to adopt reuse systems without incurring very high startup costs. CORPLEX and the Circular Plastics Alliance wanted to identify the breakeven point at which these corrugated boxes would incur a lower environmental impact than the single use equivalent cardboard boxes.

Product Footprint Assessment

This case-specific LCA assessed the impact of a CORPLEX foldable and reusable Correx® plastic box on 18 environmental indicators, including the Global Warming Potential1. Results were used to compare the relative impact of the Correx® box and of its single-use cardboard equivalent.

The Global Warming Potential (GWP), measured in kg CO2-equivalent, was assessed taking into account associated distances and tertiary packaging items used along the supply chain of both single use and reuse system, as well as pool size, system size and box losses in the reuse systems.

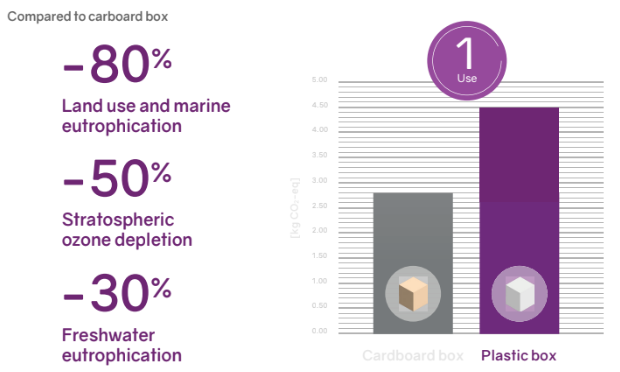

Even in a single rotation, the study shows that the global warming potential of a foldable, reusable plastic box by CORPLEX is not far from the cardboard solution footprint, with 4.38 kg CO2 equivalent, vs 2.82 kg CO2-eq. for cardboard. Nevertheless, the first advantages of polypropylene solutions are already apparent in the manufacturing process:

• The life cycle of the finished plastic box contributes 85% less to marine and 40% less to fresh water eutrophication compared to the life cycle of the cardboard box2.

• The production of the plastic box allows a reduction in the environmental impact category stratopheric ozone depletion by 50% compared to the cardboard box. The protection of the ozone layer remains a particularly important challenge.

Plastic Boxes Exhibit Sustainability Advantages Compared To Cardboard, EVEN In A Single Use Context

Reusable Plastic Box, Lower Carbon Footprint Than Cardboard

Life Cycle Footprint Assessment

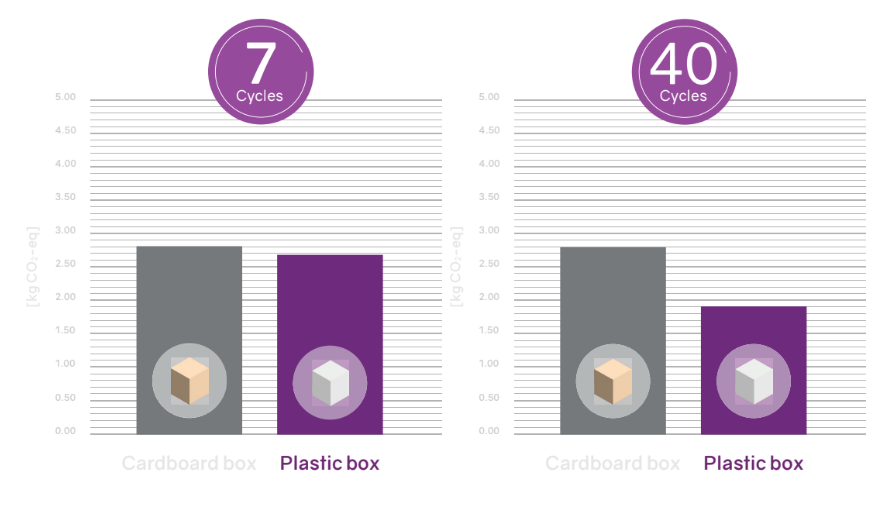

Considering the whole life cycle footprint for both cardboard boxes and plastic boxes, The LCA Centre study has established the breakeven point at which the number of reuses of plastics renders a box use of lower GWP than for the single use of cardboard. Losses in the product pool for each rotation were taken into account.

It appears that the GWP breakeven point is situated after the sixth use of a plastics solution box. From the seventh cycle onwards, the warming potential of CORPLEX Correx® Flower Box has proven to be lower than single use of cardboard box.

After 6 Cycles

Plastic box footprint is lower than cardboard box.*

*This is dependent on the design of the Reuse system: pool size, system size, replenishing rate, and packaging loss. In the specific case of the Correx® foldable and reusable box for the transport of cut flowers, the GWP was lower than for the single-use cardboard box after the 6th cycle of use.

A Potential Of 40 Reuses

From the 7th cycle onwards, the GWP potential of

the foldable and reusable Correx® box has proven

to be lower than the single use cardboard box. With a life expectancy of 40 cycles, the CORPLEX Correx®

Flower Box largely exceeds the amount of use-re-

turn-reuse cycles needed to outperform the carbon footprint of the single-use cardboard box.

Multiplying The Levelers To Reduce Carbon Footprint

PRIVILEGE MONO MATERIAL

CORPLEX strives to produce

packaging solutions with a single material, using its technical characteristics at best to meet the clients’ requirements.

This is done to facilitate recycling since the main obstacle to recycle products is the need to separate and sort materials that cannot be recycled together.

USE RECYCLED MATERIAL AS MUCH AS POSSIBLE

CORPLEX endeavours itself to use the highest possible percentage of recycled material in all of its products, thus helping companies stay ahead of government- mandated minimum recycled content.

Through our Plastics Recovery Program, we buy our products back to reuse the material to make new products, without downgrading. Once the product reaches the end of its useful life

it can be brought back directly to CORPLEX, where it gets ground and remanufactured into a new product.

OPTIMIZE SPACE IN RETURN TRANSPORT

When our packaging solutions

have allowed safe and efficient

transportation of goods, it is

time to take them back to the

distribution center to be filled

and reused again.

A step CORPLEX has not forgotten: our products are indeed designed to collapse flat for maximum space optimization. For example, our boxes are fully foldable, occupying little space when not in use and making it for very efficient truck returns.

Linear vs Loop: A Logistic Challenge

As far as logistics is concerned, the idea of “cycle” also prevails. The supply chain, which enables the production and then the routing of goods, must itself function as a closed circuit.

Of course, the habit of “produce and forget” in a linear approach is not always easy to forget… but our solutions greatly help our clients implement loop logistics:

Firstly, because CORPLEX does not only deliver packaging products, but acts as a service provider, we have set up services such as Plastics Recovery Scheme, making us partners of our clients’ supply chain, allowing it to become circular.

Another of our strength is our excellent communication and the ability to address our customers’ complex needs. These are vital elements in supply chain management: whether It’s the design of the product, It’s implementation and use, or the day-to-day management of volumes transported, we take everything into account for a tailor-made offer.

MANY OTHER BENEFITS

CORPLEX JOINS FORCES WITH THE CIRCULAR PLASTICS ALLIANCE

Circular Plastics Alliance aims at a full potential reuse of 100% collected and recycled plastics. It offers solutions in the entire logistic value chain: from growers to consumer B2B and B2C. Complete portfolio of circular solutions starting from primary packaging up to secondary- and transport packaging.

The Alliance offers turnkey solutions to reusable packaging solutions, forging partnerships with ‘Best in Class’ designers, manufacturers, distributors, collectors, and recyclers to ensure the application of a closed-loop ecosystem.

CONTACT

For further information, please contact us or scan our QR Code.